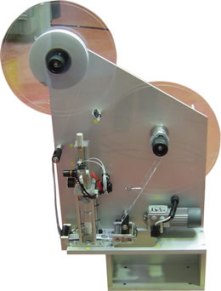

Induction Sealing Machine

Punch & Seal

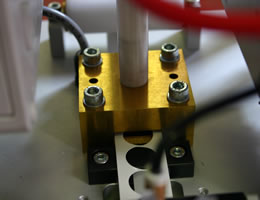

- Ceramic punching and induction

- Sealing system for single stroke

- Foil cutting and sealing

Features

- Compact device to fit into any kind of filler/sealer

- High quality seals die cut from reel fed material

- Fast cycle times

- Accurate foil location and sealing without a cap

The Relco Punch&Seal is an extremely compact and highly efficient induction sealing device which is used to cut foil from a reel into the required seal profile, locate the seal onto the container and induction weld in place, all in a single downward stroke. The power of the Relco induction sealing system combined with the small stroke of the Punch&Seal unit allows for extremely fast cycle times, in many cases less than 1 second for the complete operation. This patented device uses the unique Relco ceramic cutting technology providing a cutting face which is over 4 times the hardness of equivalent tool steel punch and die sets.

Using the Punch&Seal system a hermetic seal can be made on any container or over any other aperture without the conventional requirement of a cap and screw thread. Many advantages are available to the user including the ability to light-weight bottles and caps by removal of the thread and the ability to sterilise the foil before application to ensure a perfectly clean seal. The Punch&Seal is also ideally suited to Aseptic and other ESL filling systems allowing the hermetic sealing of containers whilst they are still within the aseptic/sterile atmosphere. The Punch&Seal unit is designed to be powered by the Relco P-800 induction generator.

This is an extremely compact device requiring no external cooling which can be fitted into almost any kind of filler/sealer with very little modification.