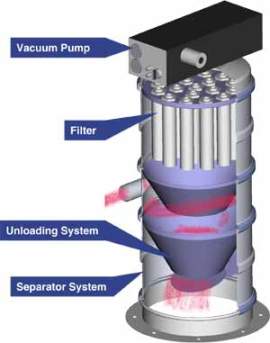

Vacuum Conveyors VR

The star of the vacuum conveyors because of its unique modular design. The VR series is used in all industries where bulk materials are conveyed. They are small and lightweight and come with many options to choose from to fulfil your demand for a high quality conveyor at a fair price and with quick delivery times.

We do the product configuration for you and help to find the best suitable solution for your application on the basis of know-how, our product database or custom tests with your particular product.

VR vacuum conveyors are available in three different sizes. The number indicates the diameter of the separator container (in mm):

- VR 170: 40 - 600 kg/h conveying capacity

- VR 315: 150 - 2500 kg/h conveying capacity

- VR 450: 500 - 6500 kg/h conveying capacity

Containers in stainless steel 1.4301 / 304,

316L optional, Ra < 0,8 μm Seals in Silicone rubber (FDA), Nitrile or EPDM

Here a brief overview about the innumerous different functional modules, which make our VR Vacuum Conveyors so flexible:

Vacuum pumps

- More than 50 MULTIJECTOR® types for Vacuum Conveying

- Multijectors completely in stainless steel (CIP-ready)

- Electrical vacuum pumps as required Integrated filters

- Modular filter-elements, lightweight, easy access

- Sintered HD-PE filter candles (5 μm), long lasting

- Polyester fabric teflonized filter cartridges (0,1 μm)

- Stainless steel filters

- Filters for hazardous / unhealthy materials

- Antistatic filters

- Filterbags with Teflon-membrane Integrated filter cleaners

- Back blow air shock systems

Suction modules

- Suction diameters ø 19-100 mm

- Radial suction modules with check valve

- Tangential suction modules with cyclone insert

- Clamp connections as required

Discharging modules

- Large diameters for discharging

- Active (cylinder) and passive (gravity balanced) discharge modules with flaps

- Butterfly valves with big discharge diameters

- Fluidizers and piston vibrators for better product flowability

- Valves and adaptations according requirements

Connectors for discharging

- Flat- or cone-flanges

- Collector tanks with liquid-release

- Textile connectors, submersion tube elements

- Individual adaptations and system integrations

Controls

- Very small pneumatic controls

- Automatic level detector control systems

- Preparation for SPS/PLC-controllers

Accessory

- Suction lances and balancers for manual use

- Product feeding stations

- Suction hoses and pipes

- Frames for wall fastening, special attachments

- Trolleys and lifts for mobile use of the conveyor

The first Vacuum Conveyors according to ATEX!

All new vacuum conveyors of the VR and PPC series are ATEX certified in accordance with directive 94/9/EG for the Explosioni Zones 1, 2, 20, 21 and 22.

EC-type examination certificate No. TÜV 02 ATEX 7005 X. For safe operation special terms/conditions apply. II 1 D c 80°C / II 2 GD 100°C Special Conveyors for Zone 0 available.